ECE1388F VLSI Design Methodology

Final Project:

Cache Chip Design

Jennifer Pham

Cintia Man

Shahriar Shahramian

Oleksiy Tyshchenko

January 31, 2005

1.

Introduction

This document focuses on the design of a synchronous write

through cache memory which implements least recently used (LRU) algorithm for

efficient data access. In the LRU

algorithm, the content of the least recently used cell is being replaced

whenever a write cycle is executed. The

content of the most recently used cell remains untouched in the cache. The cache chip consists of address and data

path. The address path is responsible for mapping the global memory address

(typically from external DRAM) to the physical location of data in the cache.

The data path returns the content of the physical memory location to the

requesting device (typically from a processor or controller). The address path is implemented as

2.

System

Functionality

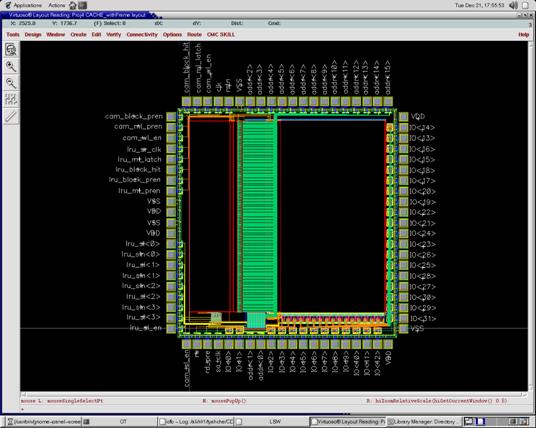

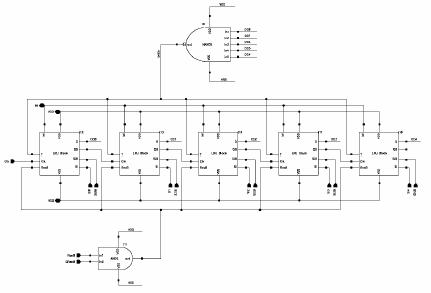

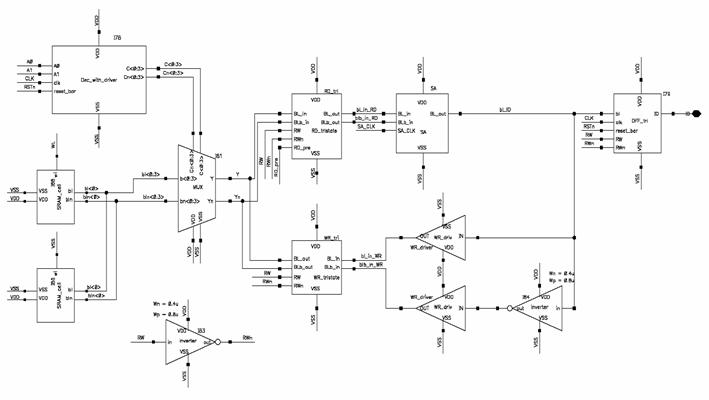

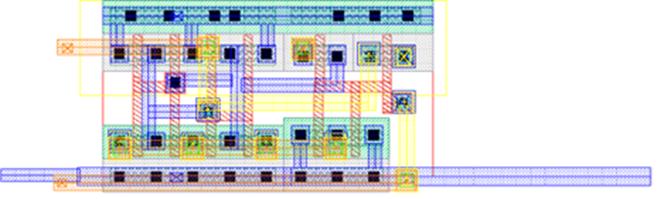

Figure 2.1

illustrates the overall block diagrams of the cache chip. The processor is

assumed to have an address space of 16 bits. The address bits (15:0) are

latched with Flip Flops before they are sent to the

·

·

SRAM:

256 Rows x 4 Blocks x 32 Bits

Figure 2.1: System

Block Diagram

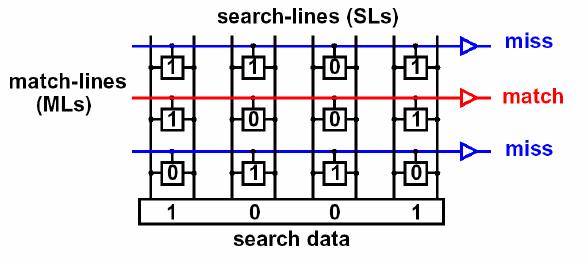

When it comes to

replacing an element in the Cache, an LRU algorithm has been employed. A custom

LRU CAM block has been designed for which its

The over all

algorithmic description of the behavior of our Cache chip during READ/WRITE

cycles is as follows:

READ HIT

1.

2.

The

least 2 significant bits of the address are used to select the appropriate SRAM

block.

3.

The

data is read from SRAM and sent back to the processor.

4.

The

corresponding LRU CAM ROW COUNTER is reset to 00000.

READ MISS

1.

2.

The

processor is notified and the LRU CAM is searched with patters to find the LRU

element.

3.

In

the meanwhile 4 words of data corresponding to the 14 most significant bits of

the address are brought from main memory.

4.

The

data from the main memory is also sent to the processor.

5.

LRU

DECISION block selects the LRU CAM row and the new address is written in the

row while 4 new words are stored in the SRAM in the same row number.

6.

The

corresponding LRU CAM ROW COUNTER is reset to 00000.

WRITE HIT

1.

2.

The

least 2 significant bits of the address are used to select the appropriate SRAM

block.

3.

The

new data coming from the processor is updates in the SRAM.

4.

In

the meanwhile, the data in the main memory is also updates. This is necessary

as the Cache is a write through Cache.

5.

The

corresponding LRU CAM ROW COUNTER is reset to 00000.

WRITE MISS

1.

2.

The

processor is notified and the LRU CAM is searched with patters to find the LRU

element.

3.

In

the meanwhile 4 words of data corresponding to the 14 most significant bits of

the address are updated and brought from main memory.

4.

LRU

DECISION block selects the LRU CAM row and the new address is written in the

row while 4 new words are stored in the SRAM in the same row number.

5.

The

corresponding LRU CAM ROW COUNTER is reset to 00000.

In terms of

division of tasks, here is an estimate:

·

LRU

Block Circuitry: Shahriar

·

·

SRAM

Column Circuitry: Jen

·

Peripheral

Circuitry for LRU,

·

System

Integration: All team members

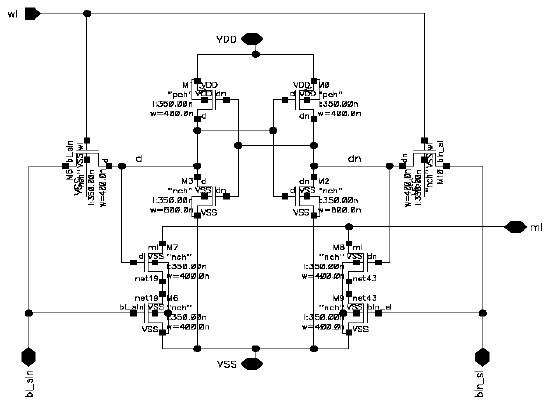

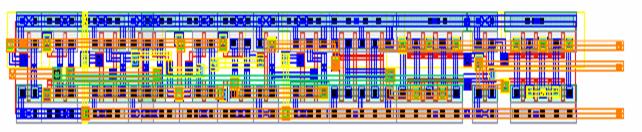

3. LRU Design

a) Circuit Schematic

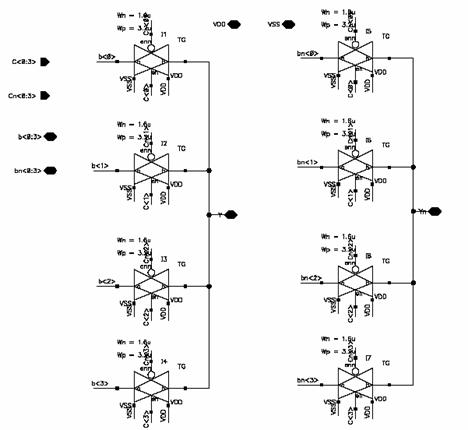

Figure 3.1:

LRU

Figure 3.2:

LRU

Figure 3.3:

LRU

Decision Block Schematic

b) Cell Layout

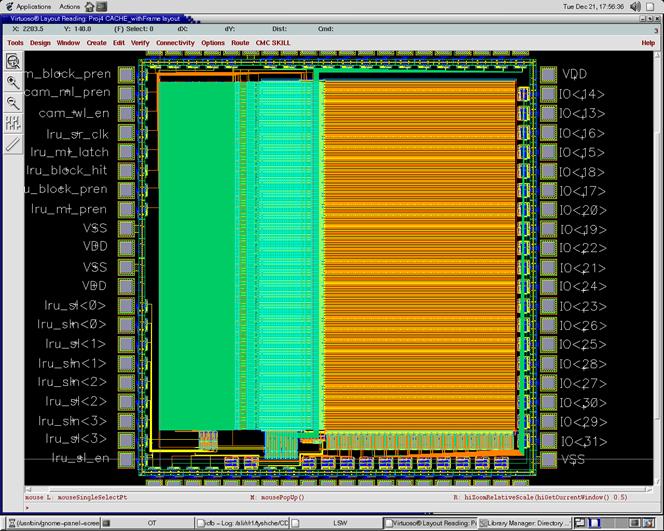

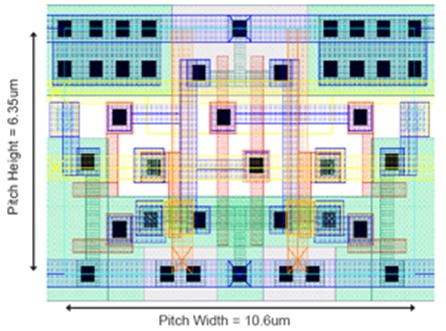

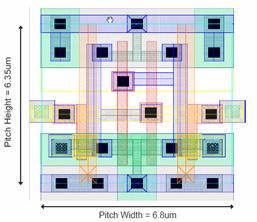

Figure 3.4:

LRU

Figure 3.5:

LRU

Decision Block Layout

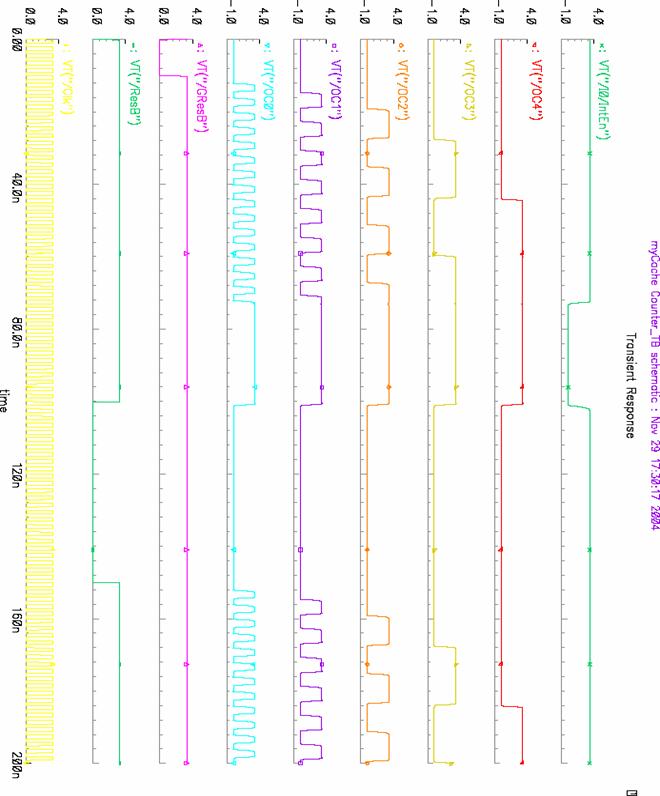

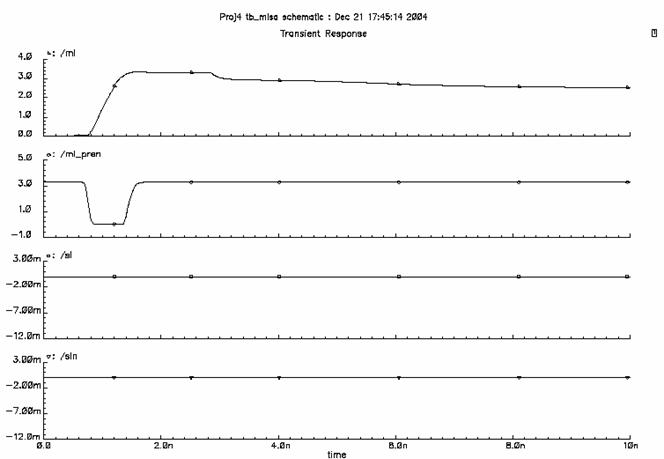

c) Simulation Results

4.

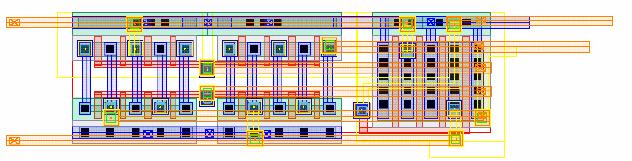

CAM

Design

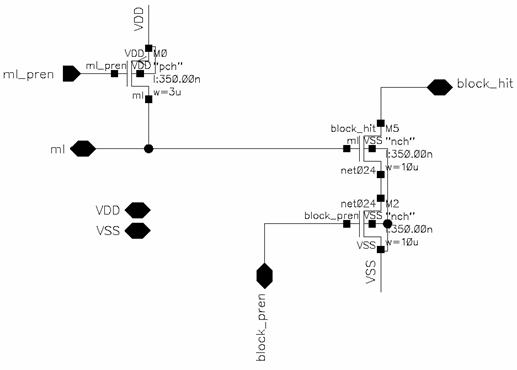

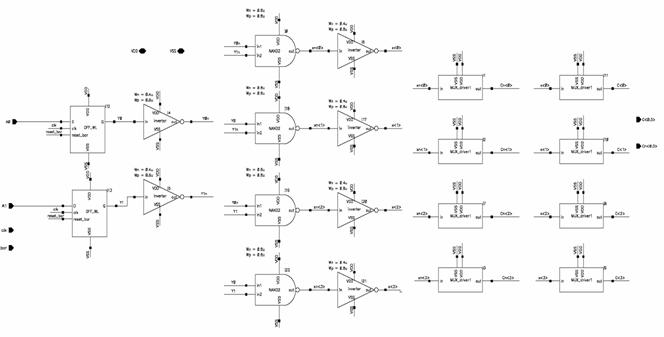

a) Circuit Schematic

Figure 4.1:

Figure 4.2:

Figure 4.3:

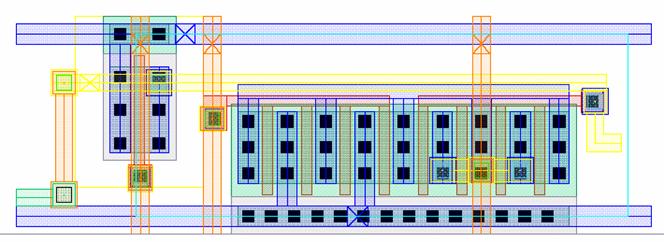

b) Cell Layout

Figure 4.4:

Figure 4.5:

MLSA

Layout

c) Simulation Results

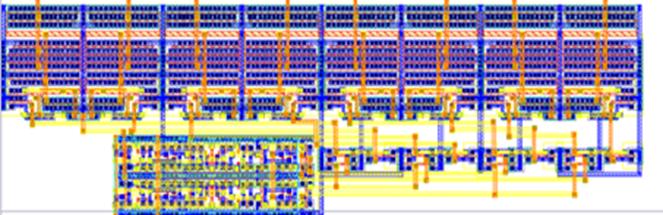

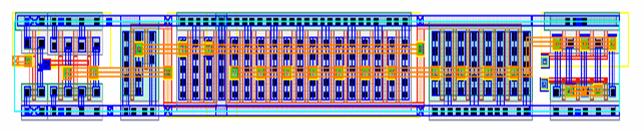

5.

SRAM Design

a) Circuit Schematic

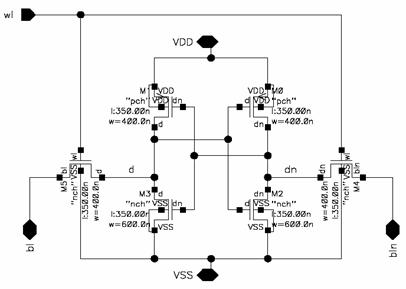

Figure 5.1:

SRAM

Column Circuitry

Figure 5.2:

SRAM

6T Cell

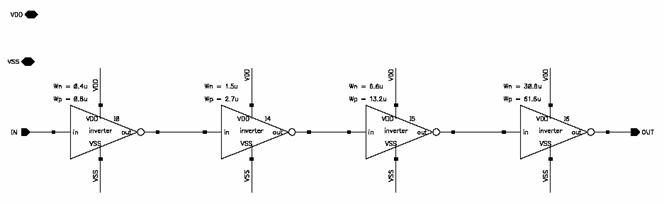

Figure 5.3:

Column

Decoder

Figure 5.1:

Column

Multiplexer

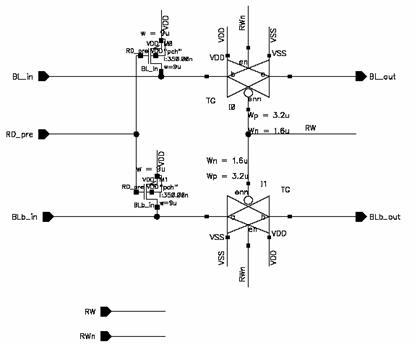

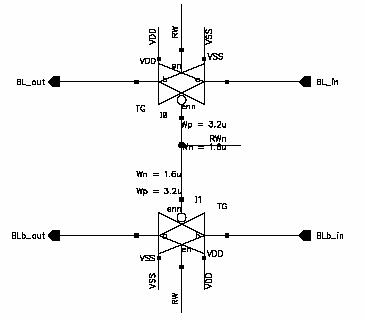

Figure 5.2:

Read

Tri-state Circuitry

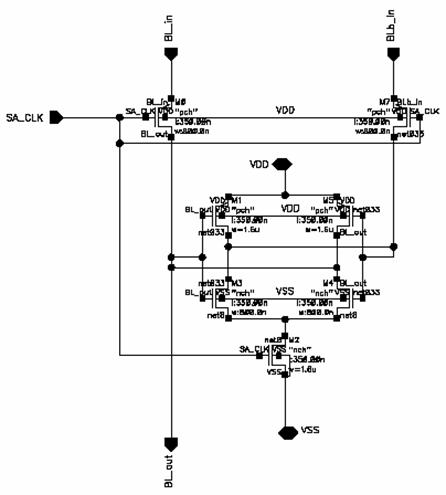

Figure 5.3:

SRAM

Sense Amplifier (SA)

Figure 5.4:

Write

Tri-state Circuitry

Figure 5.5:

Write

Bit-line Driver

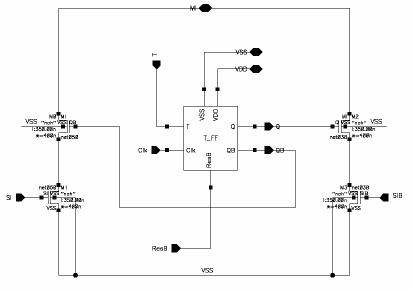

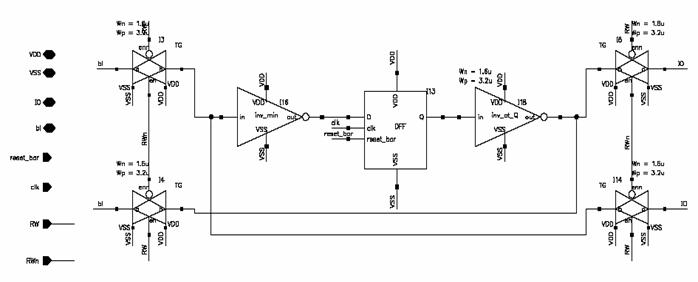

Figure 5.6:

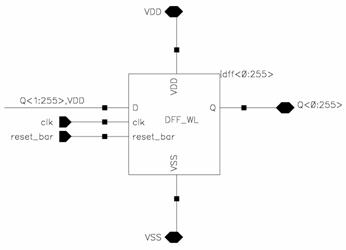

Input/Output

Flip Flop

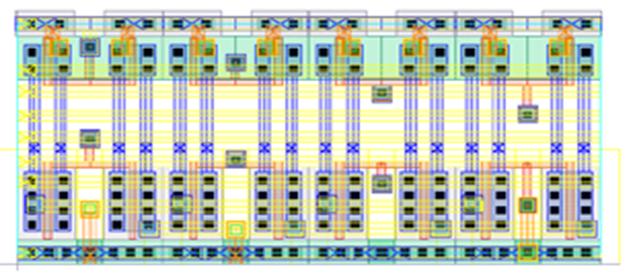

a)

Cell

Layout

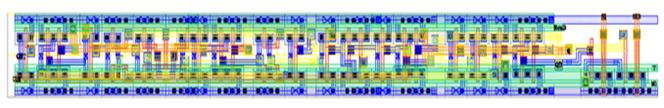

Figure 5.7:

SRAM

Cell Layout

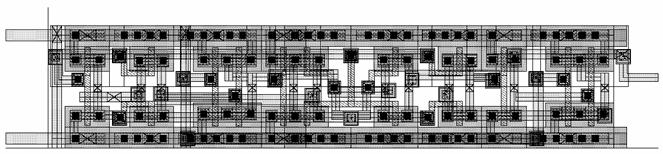

Figure 5.8:

Column

Decoder Layout

Figure 5.9:

Column

Multiplexer Layout

Figure 5.10:

Read

Tri-state Layout

Figure 5.11:

SRAM

Sense Amplifier Layout

Figure 5.12:

Write

Tri-state and Bit-line Driver Layout

Figure 5.13:

Input/Output

Flip Flop Layout